The SARC compressor

20% of the global industrial electric energy consumption goes to the gas compressors’ operation. The future saving potentials are estimated to be no higher than 15% for the established maximum power and power-to-weight ratio. Our gas compressor, SARC, can go up to 38% energy saving and depending on the size of the application: 40% higher output pressure, 48%-61% weight reduction and 74%-86% size reduction.

SARC is a rotary, oil-free gas compressor designed to address the most demanding requirements of any application. Its novel design combines the benefits of oil-free and lubricated compressors to a device up to 5 times smaller than the competition.

Based on a clean-sheet design, it is a 5x smaller & lighter isothermal compressor, oil-free, vibration-free, high efficiency, high performance, high flow rate, capable of operating in extreme conditions.

Experimental set up and validation of the 4th prototype

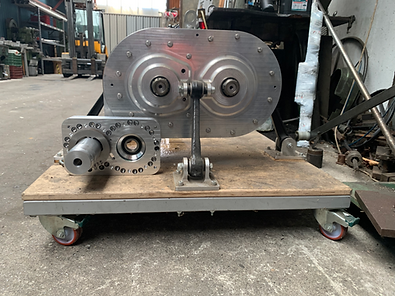

All parts were constructed from Aluminum 7075-T6 and assembled in the rotary compressor, as shown in Figure 16. The experiments were conducted in the Laboratory of Applied Thermodynamics (Aristotle University of Thessaloniki), an associate member of EARPA (European Automotive Research Partners Association) that is also certified by QMS, conforming to the requirements of ISO 9001:2008. For measuring the pressure, the AVL X-Ion high-speed, modular data acquisition system and power analyzer were used. The AVL X-Ion is capable of reading signals at very high-frequency sampling rates (>100 kHz in this case) provided by the Kistler 5011 signal amplifier connected to the in-cylinder pressure sensor. The compressor was driven by a variable frequency motor which is set to a constant speed of 2576 rpm in the experiment. The outlet pressure was measured by the outlet pressure sensor, located at the position where theoretically the peak pressure would be developed. Interestingly, the measured peak pressure at 2576 rpm did not differ essentially from the CFD results. CFD simulations refer to the first five rotations with a peak pressure of 20.477 bar, whereas the measured rotations during the test were more than 1,000.

The final assembly of the rotary piston compressor and photographs from the experimental campaign.The peak pressure fluctuates between the values of 15.53 and 21.29 bar.

Our last prototype focused on testing the heat management of the compressor. This prototype ran for 1.2 hours increasing gradually its speed from 1,000rpm to 5,500 rpm.

Our last prototype (here cooled with oil), compared to the previous prototype and the electric motor